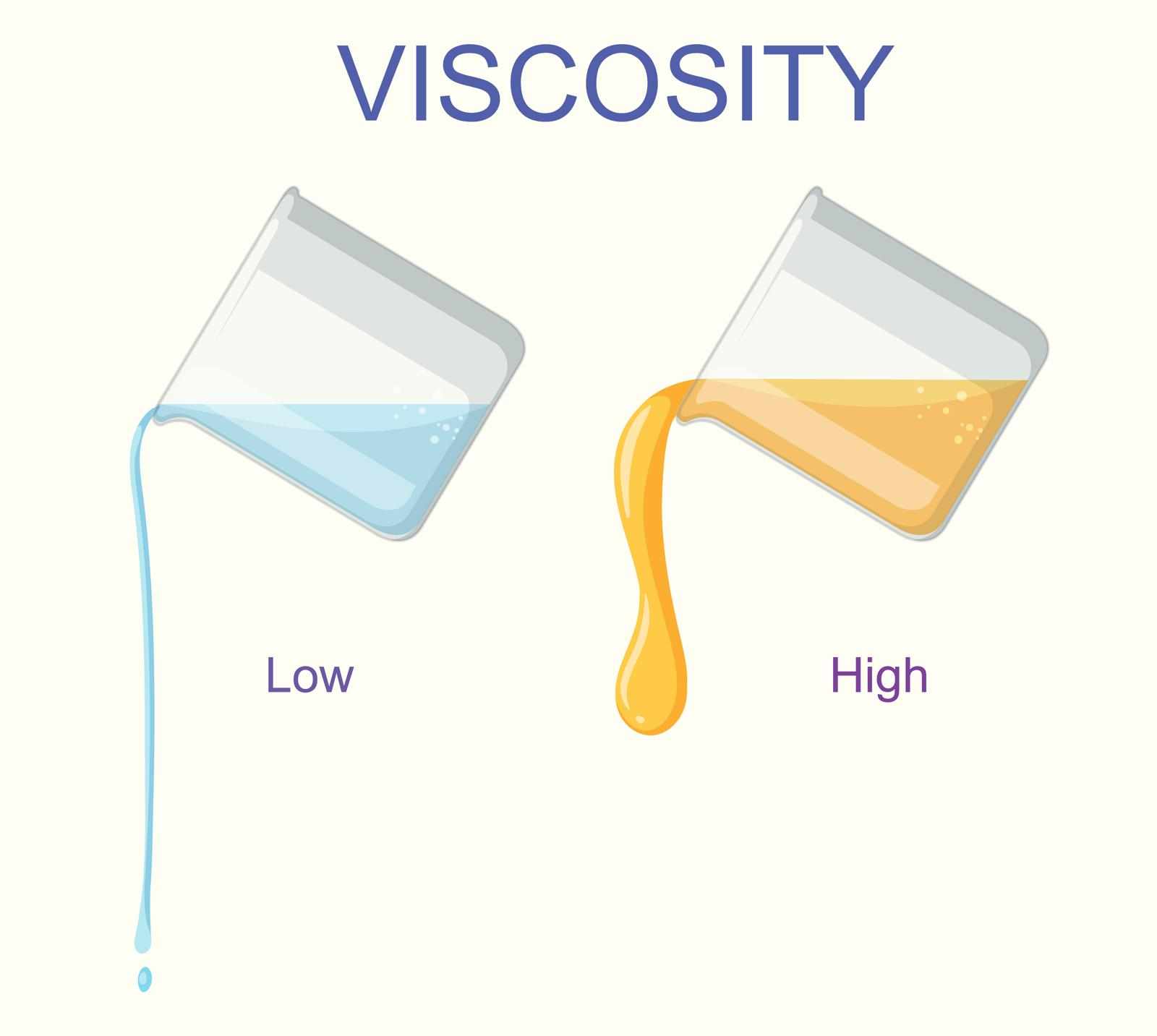

When it comes to lubricants, every detail matters — and viscosity is one of the most critical. The ability of an oil to maintain the right viscosity across temperature changes directly affects how well engines and machinery perform. That’s where viscosity modifiers, or oil viscosity improver, come in.

These additives are polymers designed to make oils more stable under varying conditions. But their performance doesn’t depend on the additive alone — several external and internal factors influence how effectively an oil viscosity improver performs in real-world applications.

Let’s break down the seven key factors that can make or break the performance of viscosity modifiers in oils.

1. Base Oil Compatibility

Every oil viscosity improver interacts differently with different base oils. The chemical composition, polarity, and viscosity index of the base oil determine how well the modifier can dissolve and function.

For instance, mineral base oils and synthetic base oils vary significantly in their molecular structure. A polymer that performs efficiently in a mineral base may show reduced effectiveness in a synthetic blend if it doesn’t properly disperse.

Choosing a viscosity modifier that matches the base oil type ensures smoother molecular interaction and maintains consistent viscosity across operating temperatures.

2. Temperature Range

Temperature swings are the ultimate test for viscosity modifiers. These additives are designed to keep oil from thinning out at high temperatures and thickening too much at low temperatures.

However, every oil viscosity improver has a thermal stability limit. At excessively high temperatures, polymer chains can degrade, reducing their thickening ability. On the other end, extremely low temperatures may cause the polymer to collapse or separate, leading to poor flow properties.

To maximize performance, it’s vital to select a modifier that matches the temperature demands of the equipment — whether it’s a high-performance engine or an industrial compressor.

3. Shear Stability

In moving machinery, oil is constantly subjected to shear forces — the stress created by fast-moving parts and tight clearances. Some viscosity modifiers can lose effectiveness under these conditions if their long polymer chains break down.

High shear stability is especially important in modern engines where tight tolerances and high-speed operations are common. A high-quality oil viscosity improver should resist mechanical shearing to maintain its molecular integrity, ensuring long-term viscosity retention and consistent lubrication performance.

4. Molecular Weight and Structure

Not all polymers are created equal. The molecular weight and architecture of a viscosity modifier directly influence its performance.

Linear polymers provide a strong thickening effect but may have lower shear stability. In contrast, star-shaped or comb-like polymers often strike a better balance between viscosity control and durability.

Selecting the right molecular design helps the oil viscosity improver deliver consistent performance without causing deposit formation or filter plugging — two common issues caused by poor-quality polymers.

5. Additive Synergy and Formulation Balance

Viscosity modifiers don’t work in isolation. Oils also contain detergents, dispersants, antioxidants, anti-wear agents, and other additives. The chemical balance among these components determines whether the viscosity modifier can perform optimally.

For example, some additives may compete for surface sites or interfere with the polymer’s solubility. Proper formulation ensures that the oil viscosity improver works synergistically within the package — maintaining a balanced viscosity profile while supporting oxidation resistance and cleanliness.

Formulators must carefully test compatibility to prevent additive antagonism and to maintain the lubricant’s intended performance characteristics.

6. Operational Conditions

The working environment significantly affects viscosity modifier behavior. Factors like load intensity, pressure, and contamination can alter how polymers perform over time.

In high-load industrial applications, continuous stress can accelerate polymer degradation, while in off-road or marine environments, contaminants like soot, fuel, or water can disrupt oil stability.

Selecting an oil viscosity improver suited for the application type — whether for automotive, hydraulic, or gear oil — ensures optimal resistance to these stresses. This not only extends lubricant life but also protects critical components from wear and failure.

7. Degradation and Oxidation Resistance

Finally, long-term performance depends on how well the viscosity modifier withstands degradation. Over time, heat, oxygen, and mechanical stress can cause polymer breakdown, leading to loss of viscosity control and oil thickening.

Advanced polymers are engineered to resist oxidation and maintain molecular stability under harsh conditions. An oil viscosity improver with superior oxidative resistance ensures the oil remains effective across extended drain intervals, improving both efficiency and cost-effectiveness for end users.

Bringing It All Together

Performance in viscosity modifiers isn’t a single-variable equation — it’s a complex balance of chemistry, temperature, mechanical stress, and formulation design. The right polymer must be matched to the right oil and operating conditions to deliver consistent, reliable performance.

Whether you’re developing lubricants for automotive engines, industrial gearboxes, or hydraulic systems, understanding these seven factors helps you choose the right modifier and design more stable formulations.

Partner with Innovation That Performs

In a market where efficiency, durability, and performance define success, choosing the right oil viscosity improver partner makes all the difference. This is where Top Polymers stands out — delivering high-performance polymer solutions engineered for stability, shear resistance, and long-term reliability.

If you’re looking to upgrade your lubricant formulations or optimize viscosity control under extreme conditions, now’s the time to collaborate with experts who understand the science behind every drop.

Enhance your oil performance with smarter polymer chemistry — connect with Top Polymers today and experience the difference innovation makes.

Write a comment ...