Lubricants are integral to the smooth operation of machinery, vehicles, and industrial equipment. However, it's not just the base oil that keeps things running efficiently; the additive packages for lubricants play a vital role in maximizing performance and extending equipment lifespan. These specialized additives improve the quality of lubricants, providing benefits like increased resistance to wear, corrosion, and high temperatures. In this blog, we’ll explore why these additive packages are crucial for your operations and how they can significantly boost efficiency and longevity.

The Importance of Lubricant Additives in Machinery

Lubricants themselves are designed to reduce friction between moving parts, preventing wear and tear. However, as equipment operates under varying conditions, the basic properties of lubricants often fall short. This is where additive packages for lubricants come into play. These additives are specifically formulated to enhance the properties of lubricants, providing protection against factors such as oxidation, rust, and thermal degradation.

The role of these additives is essential for equipment that operates in extreme environments. Whether your machines are exposed to high temperatures, heavy loads, or severe pressure, the right additives can help your lubricant perform optimally, ensuring that your equipment stays efficient and reliable for longer periods.

How Additive Packages Contribute to Equipment Lifespan

Equipment and machinery are significant investments for any business, and maintaining them is crucial to minimizing operational costs. One of the most effective ways to ensure the longevity of your equipment is through proper lubrication. Additive packages for lubricants contribute to this by offering enhanced protection.

For instance, anti-wear additives in lubricant packages create a protective film between the moving parts, reducing friction and minimizing wear. This is especially crucial in machinery where parts experience constant motion, such as engines, compressors, or hydraulic systems. Over time, this wear can cause significant damage, leading to costly repairs or replacements. By using the right additive packages for lubricants, you reduce this wear and tear, extending the life of your machinery.

Additionally, additives such as antioxidants prevent the oil from breaking down under heat, maintaining the lubricant's effectiveness over time. This keeps machinery functioning efficiently for longer, preventing the buildup of harmful sludge and deposits that can block critical components.

Boosting Operational Efficiency with Additive Packages

Operational efficiency is the backbone of any successful business, and lubricant additives play a critical role in enhancing it. Machinery running smoothly without frequent breakdowns or maintenance is more productive, leading to better overall performance.

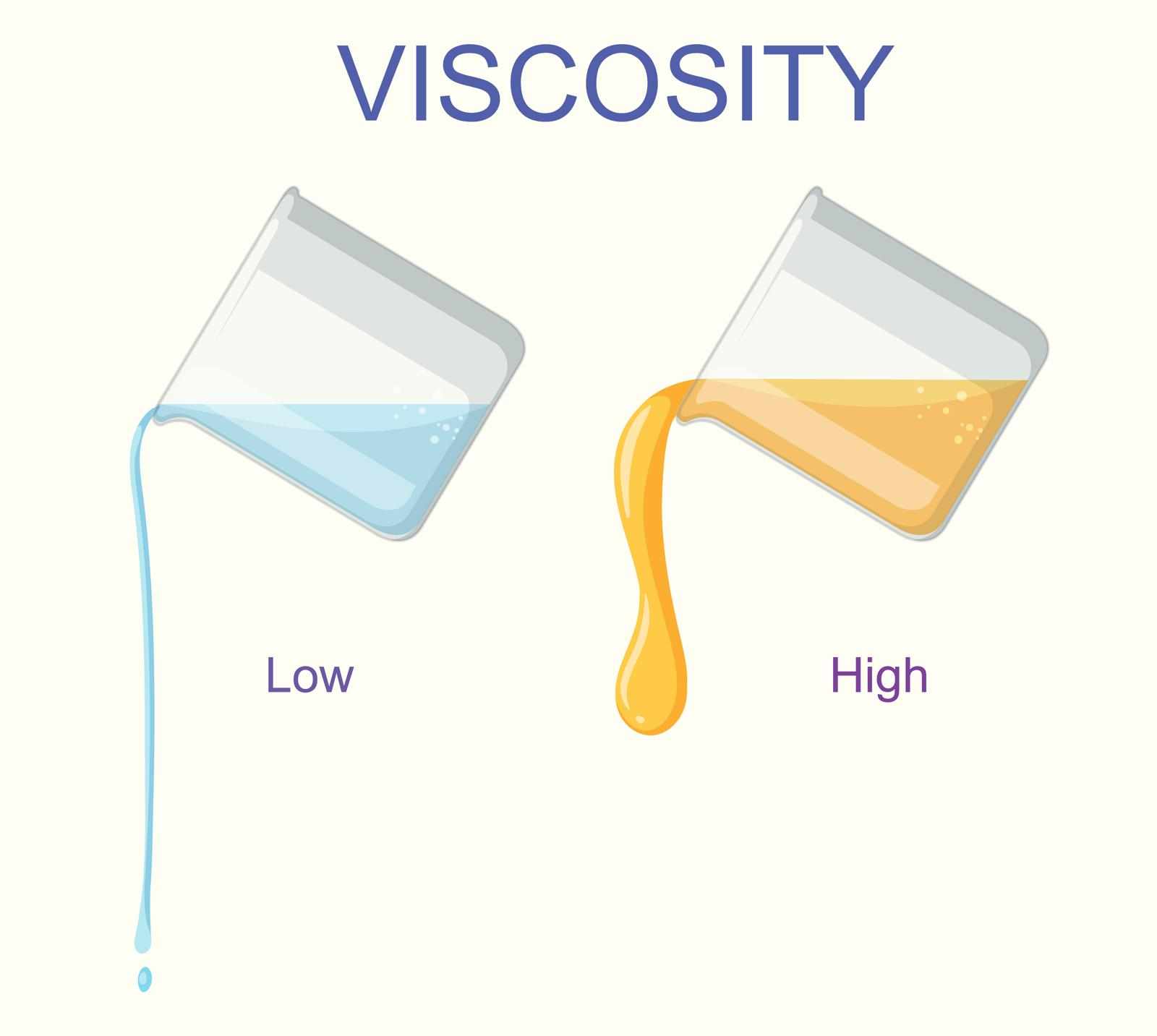

Additive packages for lubricants are designed to reduce friction and enhance the lubricating properties of oil, which directly impacts energy consumption. When friction is reduced, machines operate more efficiently, using less energy. This can lead to significant cost savings, especially in industries where machinery operates at full capacity for long hours.

Moreover, additives that improve high-temperature stability ensure that equipment can function under extreme conditions without losing efficiency. In industries like automotive, manufacturing, or heavy machinery, where operations are often carried out under high-pressure or high-temperature environments, these additives are crucial for maintaining peak performance.

Cost Efficiency through Fewer Breakdowns

A significant benefit of using additive packages for lubricants is the reduction in unplanned downtime due to equipment failure. When equipment operates with high-quality lubricants enhanced by the right additives, there is a lesser chance of malfunction or failure. This translates to fewer breakdowns, less maintenance, and fewer emergency repairs—all of which contribute to lower operational costs.

For businesses looking to optimize their processes, reducing the need for frequent repairs and downtime is a key strategy for improving profitability. The extended life of equipment through the use of high-quality additives ensures that machinery runs longer and more reliably, which ultimately saves money in the long term.

The Role of Top Polymers in Providing Quality Additive Packages

When it comes to selecting additive packages for lubricants, choosing a reliable supplier is essential. Top Polymers is a trusted name in the industry, offering high-quality lubricant additive solutions that are tailored to meet the specific needs of different industries. By choosing Top Polymers, you ensure that your lubricants are optimized for maximum performance and longevity.

Their products are designed to provide comprehensive protection against wear, oxidation, and corrosion, ensuring that your equipment remains in excellent condition. With their expertise in creating custom additive packages, Top Polymers ensures that you get the right solutions for your business needs, helping you maintain operational efficiency and reduce long-term costs.

Why You Should Invest in High-Quality Additive Packages

The performance of your machinery is only as good as the lubrication it receives. Investing in additive packages for lubricants is not just about improving performance; it’s about reducing the total cost of ownership for your equipment. With fewer repairs, longer equipment lifespan, and higher efficiency, high-quality additives can yield significant returns on investment.

If you're looking to maximize your operational efficiency and reduce maintenance costs, it’s time to partner with a trusted supplier. Reach out to Top Polymers for superior lubricant additive solutions that will enhance your machinery’s performance, boost efficiency, and extend its life.

Write a comment ...